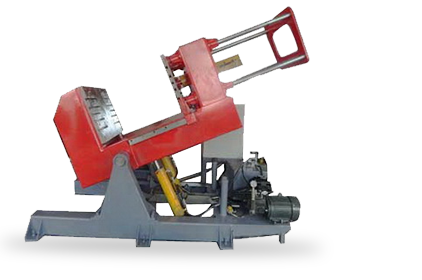

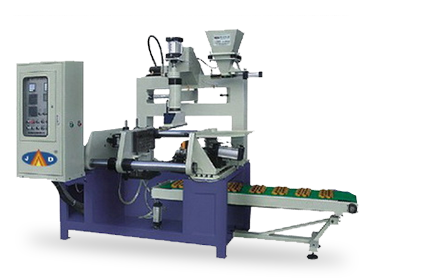

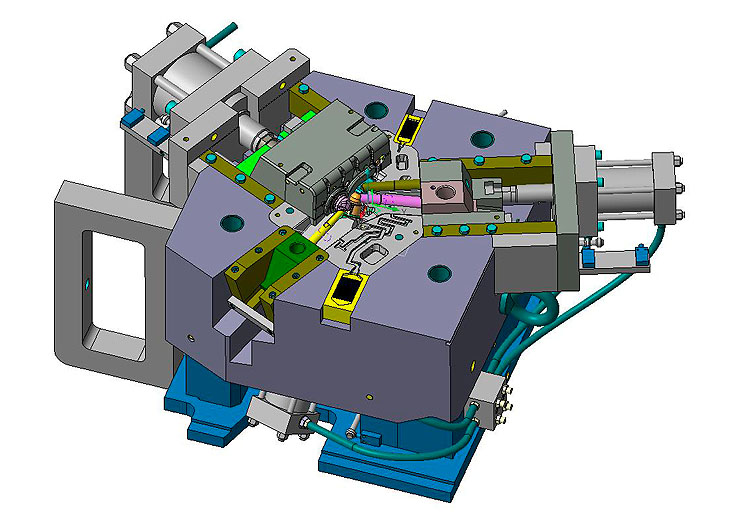

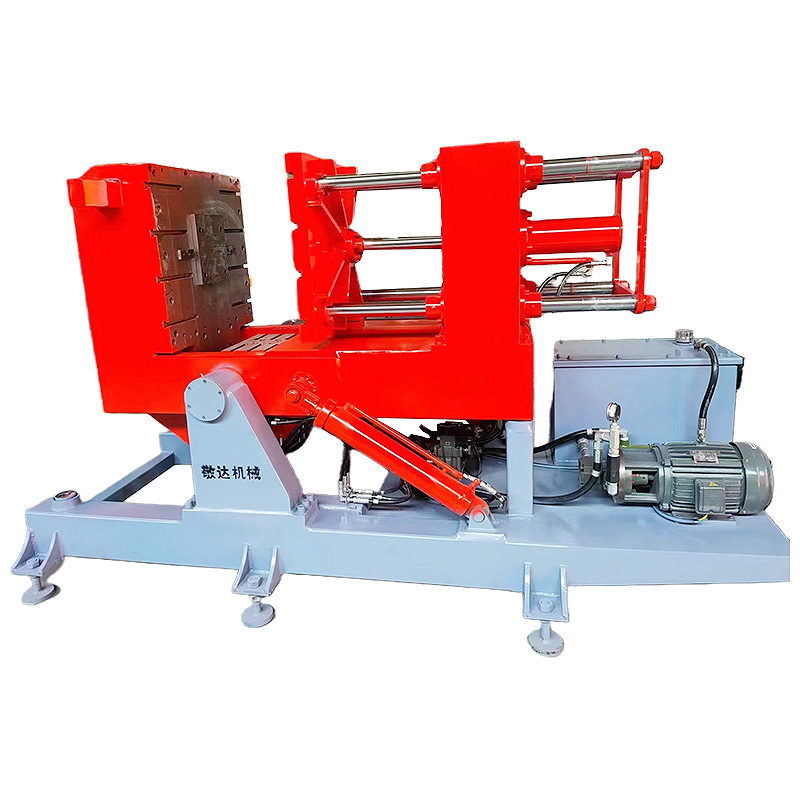

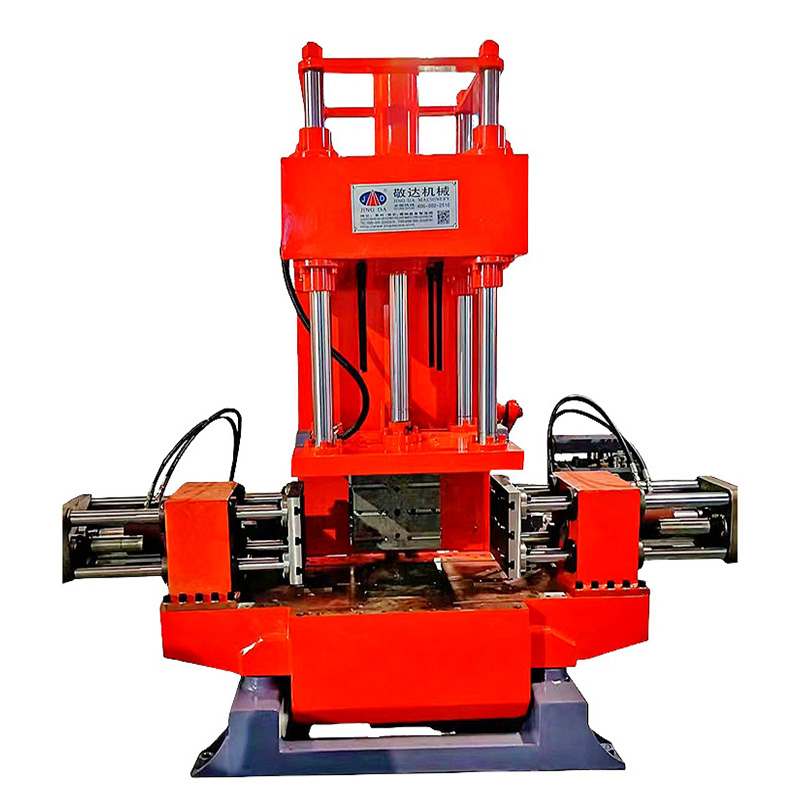

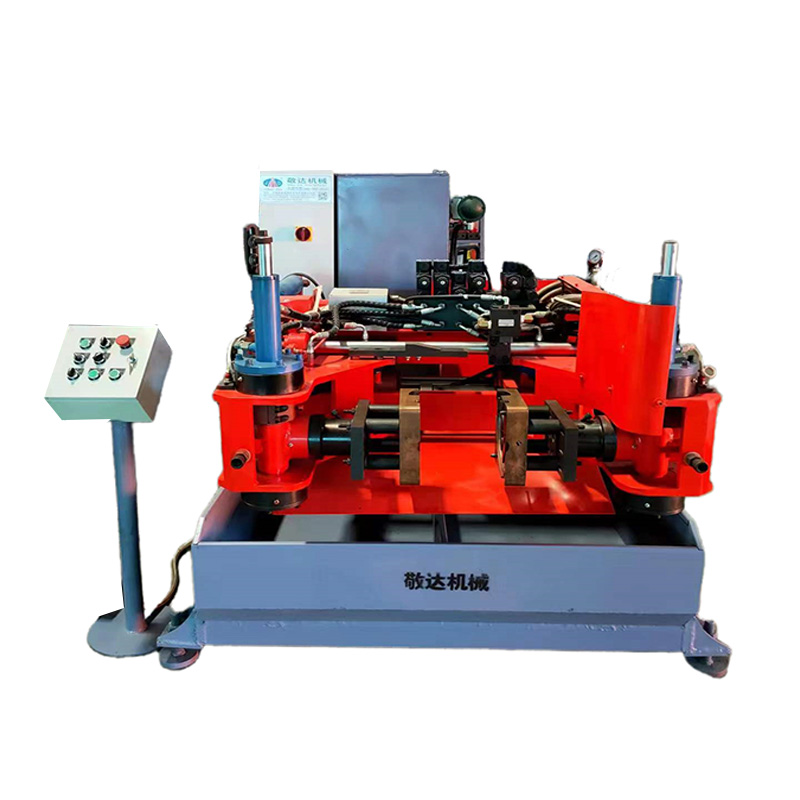

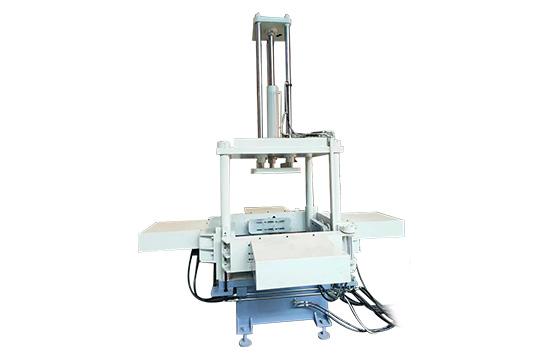

As a core shooter machine supplier, First deeply know that High Quality is key value for the enterprise long term constantly development. We are strictly eye on every process on quality control to make sure high valued item output. We are working hardly and constantly to perfect and make more effectively on our quality management system.china core shooter machine manufacturer JD-361-A.Hot Sale Heat Core Box Sand Core Machine for Casting JD-300-II 1.PRODUCT DESCRIPTION Hot box core shooter machine 2.ADVANTAGES OF PRODUCT Core shooter is widely applied in foundry industry in recent years, due to use sand core shooting machine to mould, can not only save high salary of moulding labor, because is many boxes stacked pouring, can also reduce the waste of ingate and riser, the coated sand after pouring, collapsibility is very good, good for sand. sand core shooting machine production efficiency is high, the size precision of sand mould, can be appropriately reduced processing amount. Easy operation, the casting finished produts yield high . More foundry prefer using sand core shooting machine to mould .The core shooting machine consists of three parts, such as mechanical part, pneumatic part and electrical part. This machine is mainly used to make the sand core & shell core for the sand casting industries. 3.ADVANTAGES OF COMPANY 1) Over 20 years experience in brass casting equipment. 2) First and most accepted China brand. 3) Most competitive price and quality. 4) Auto working, easy operation, save labour. 5) Short delivery time. 6) Instant aftersale service on line. 7) Import and Export License. 8) OEM. 4.APPLICATION: The sand core produced by the Core Shoot Shooting Mahcine are widely used in Brass, Copper alloy casting for Plumbling Hardware, Faucets, Valves, Car Spares, etc.. 5.SALE & AFTER-SALE SERVICE: Warranty 1 year free. Lifetime maintenance. Afersale service: instant and fluenct English service, by on line chatting, or by phone, or other way by negotiation. 6.MAIN SPECIFICATION AND TECHNOLOGY PARAMETER JD-300-II Heat core box core shooting machine (three-station core-pulling machine) Maximum weight of sand core 3.2 kg Maximum core box size (L× W× H) 350mm× 260mm× 160mm Stroke under pressure of shooting head Less than 30 mm Size of heating plate (L× W) 350mm× 20mm Core-pulling stroke below 125 mm Core-pulling stroke between front and back 50 mm Adjustment angle of core-pulling between front and back Less than 70 deg Machine weight 450 kg Heating power 6.5 kw Machine size (1250× 950× 1850)mm 7. THE CORE SHOOTING MACHINE WORKING PROCEDURE: Core box clamps----sand shooting head clamps----sand shooting----shooting 8.WHAT IS CORE SHOOTER MACHINE? A core shooter machine, also known as a core making machine, is a specialized piece of equipment used in the foundry industry. It is used to create sand cores, which are integral parts of the casting process. Sand cores are typically used to create hollow sections or cavities within a casting mold. The core shooter machine works by injecting sand or a mixture of sand and a binding agent, such as resin, into a core box. The core box is a distinct pattern or mold that defines the shape and dimensions of the core. The machine uses compressed air or a mechanical system to shoot the sand mixture into the core box, ensuring that it fills the desired areas and forms the core's shape. Once the sand mixture is injected into the core box, it is left to harden and solidify. The core box is then opened, and the solidified sand core is removed. The cores are later assembled and positioned within the casting mold before the molten metal is poured. Core shooter machines come in various sizes and configurations to accommodate different casting requirements. They offer automation and precision in the core-making process, increasing efficiency and reducing labor costs. Additionally, they allow for the production of complex and intricate cores that would be challenging to achieve manually. Overall, core shooter machines play a crucial role in the foundry industry by enabling the production of high-quality sand cores for the casting process. 9.PACKAGING & SHIPPING 10.COMPANY PROFILE Quanzhou jingda machinery co.,ltd 1)We are one manufacturer of metal foundry machinery and core shooter machinery in China. 2)We are production automatic molding machine, gravity die casting machine, compound CNC polishing machine , SPM machine(compound CNC drilling machine,CNC machining center etc.), furnace, core shooting machine, mixing sand machine and so on. 3)Our machines are extensively used in producing and machining foundry parts,metal castings, plumbing fittings, sanitary ware,car spare parts,valve for brass, aluminium, zinc, iron cast production line and others please contact us! 4)We have professional technical support and after sale service. With a whole line foundry machines,good quality, reasonable prices and stylish designs. 5)Our machines really help a lot for our customers. Products are widely used in : electric power fittings, motorcycle parts,auto parts,new energy industry,electronics, electricals, high-voltage switches, engineering machinery, aerospace castings, fans, household appliances and other professional casting production lines.Reliable quality and excellent service help our company gain a good reputation from our customers. In addition to domestic sales, our products have obtained a good market share in Southeast Asia, Africa, South America, Middle East and other parts of the world. 11.FAQ Q1. Where is your factory located ? How can I visit it ? A : Our factory is located in Quanzhou city,Fujian province,China. You can fly to Jinjiang or Xiamen air port, we will pick you up. Q2. Are you produce machine's specific parameters according to the samples? A: Yes, we produce the machine you want by your samples or technical drawings. Usually one machine have different molds and fixtures like metal polishing machine,die casting machine. Q3. What is your sample service? A: We can supply the sample testing which client want to produce if we have ready machine in stock, but the customers have to pay the sample shipping cost. Q4. What is your MOQ of your machine? A: Normally our MOQ is 1 set. Q5. Do you test all your machine before delivery? A: Yes, we have 100% test before delivery. Q6: How do you make our business long-term and good relationship? A:1. We keep good quality and competitive price to ensure our customers benefit ; 2. We respect every customer as our friend and we sincerely do business and make friends with them,no matter where they come from. Q7:Are you manufacturer or trade company? A:We are manufacturer Q8:What is your delivery time? A:Commonly,we deliver within 35 days. Q9:Can i visit your factory? A:Sure,welcome you. Q10: Can I have your quotation? A: First, please offer us the information of your material size, without these parameter, we are not able to recommend you the suitable machine. Q 11: How to operate and maintain the machine? A : First, we will provide a professional and detailed USER GUIDE to you with the machine; Second, we will debug the machine in the best status for you; At last, we also provide abroad technical training service. Q 12: Where is your factory located ? How can I visit it ? A : Our factory is located in Quanzhou city,Fujian province,China. You can fly to Jinjiang or Xiamen air port, we will pick you up. Q 13 :What's dimension of your workpiece ? A : In order to configure suitable size machine for you. we should get your info. We can professional design as your requirement. Q 14: Can you guarantee you quality? A : Of course. We are the manufacture factory ,more important, we put a high value on our reputation. Best quality is our principle all the time. You can be assured on our production completely. Our address:High end Equipment Intelligent Manufacturing Park, Plant 1,Unit 4, No. 99, Pulang Village, Xiamei Town, Nanan City, Quanzhou City, Fujian Province, China. Nearest airport:Quanzhou jinjiang Airport Contact Information: Quanzhou Jingda Machinery Co.,Ltd. Web:http://www.jingdamachine.com E-Mail:[email protected] Add: High end Equipment Intelligent Manufacturing Park, Plant 1,Unit 4, No. 99, Pulang Village, Xiamei Town, Nanan City, Quanzhou City, Fujian Province, China.

more about